Add to Cart

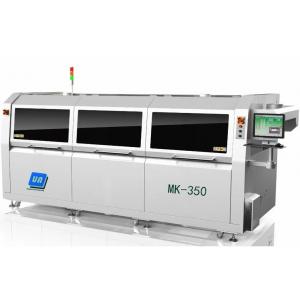

New Hot Air Lead Free Wave Solder Machine Cast Iron Solder Pot

SPECIFICATIONS

| Model No. | MK-350 | MK-450 |

| Dimensions (L X W X H) | 4560/1580/1730 mm | 4560/1580/1730 mm |

| Weight | Approx. 2000 KG | Approx. 2150 KG |

| Total power | 3 Phase AC 380V, 5 Wire 50/60Hz 37 KW | |

| Running power | 8.2 KW | |

| Preheating time | <15 min | |

| Temperature range | Room temperature~280℃ | |

| PCB width | 50~350mm | 50~450mm |

| PCB clearance | Top 120mm / Bottom 25mm | |

| Conveyor direction | L to R (Option: R to L) | |

| Conveyor height | 750±20mm (Entrance) | |

| Conveyor speed | 300~1800mm/min | |

| Preheating zones | 3 bottom hot air preheating zones (Option: 2 groups preheating/3+3 blower motors, better energy efficiency for small size PCB production) | |

| Temp control mode | PID+SSR | |

| Control system | PC+PLC | |

| Spray system | Internal stepping motor | |

| Conveyor finger | Heavy duty double-hook finger | |

| Solder pot capacity | 480 KG | 550 KG |

| Conveyor width adjust | Manual control by handwheel (Option: electric control) | |

| Solder pot operation | Electric control | |

| Solder pot material | Cast iron + Enamel processing | |

| Cooling mode | Forced air cooling | |

PRODUCT DESCRIPTION

PHOTO SHOWS

3D Drawings

PCB input system

Hot air preheating Module design

Cast iron solder pot